HTR450 Trench Roller With 45cm Drum Size and Diesel Englne

Weight

580kg

Engine Manufacturer

KAMA 178FE

Drum Size

450mm

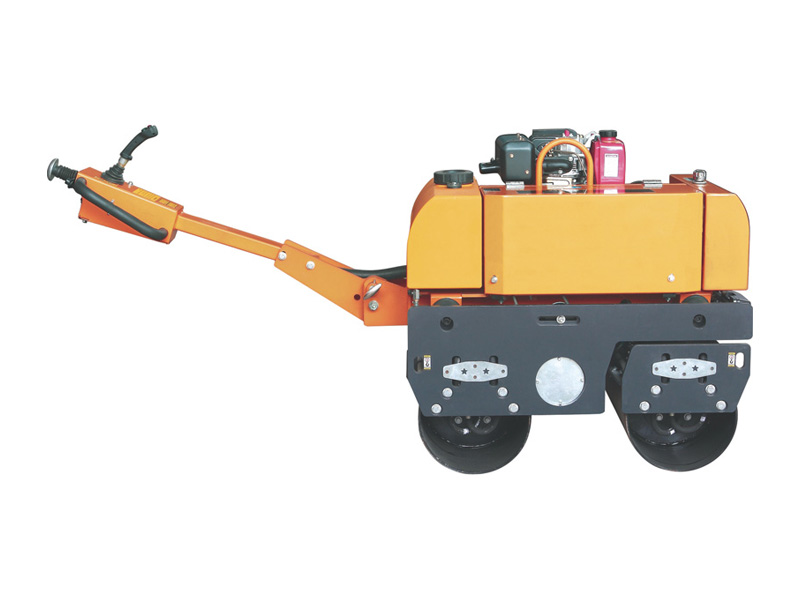

HDR500D Walk-Behind Rollers With Weight 550KG and 55cm Drum Size

Weight

550kg

Engine Manufacturer

Honda 9HP engine or 178FE KAMA Diesel

Drum Size

550*377mm

HDR600E Economical Walk-Behind Rollers With Weight 580KG and 60cm Drum Size

Weight

580kg

Engine Manufacturer

KAMA 178FSE

Drum Size

600mm

HSR600B Single Drum Walk-Behind Rollers With 300KG and 60cm Drum Size

Weight

300kg

Engine Manufacturer

Gasoline Engine(HONDA or LONCIN)

Drum Size

600x426mm

HDR600D Walk-Behind Rollers With Weight 720KG and 65cm Drum Size

Weight

720kg

Engine Manufacturer

Honda 13HP engine or 186FE KAMA Diesel

Drum Size

650mm*377mm

HDR700D Walk-Behind Rollers With 65cm Drum Size and HONDA GX390 Engine

Weight

740kg

Engine Manufacturer

Gasoline or Diesel Engine

Drum Size

650mm

HDR800DZ Walk-Behind Rollers With 852KG and 65cm Drum Size

Weight

852kg

Engine Manufacturer

Diesel engine 186FE

Drum Size

650mm

HDR900D Walk-Behind Rollers With 880KG and 75cm Drum Size

Weight

880kg

Engine Manufacturer

HONDA GX390 or Diesel engine 186FE

Drum Size

750mm

HDR900DZ Walk-Behind Rollers With 920KG and 75cm Drum Size

Weight

920kg

Engine Manufacturer

Diesel engine 186FE

Drum Size

750mm

Horizont's Walk-Behind Roller Compactors

- Horizont Single-Drum Patching Rollers

Our single-drum patching rollers are ideal for small asphalt repairs where larger tandem rollers won't fit. They are reliable, perform excellently, and are favored by contractors and public works departments. Each roller features a hydrostatic-drive system for smooth, variable-speed operations and quick acceleration and braking, showcasing Horizont's commitment to quality.

- Horizont Tandem Double-Drum walk behind roller compactor

For larger asphalt compaction tasks, Horizont's double-drum rollers step up to the plate. The HDR600E, our proud tandem offering, boasts a sleek design perfect for navigating narrow spaces without compromising on power. These dual-purpose rollers are not just for asphalt; they excel in compacting granular soils, making them indispensable in your machinery fleet.

- Horizont HTR450 Trench Walk Behind Roller Compactor

The HTR450 excels in delivering top-notch compaction results in trenches, sewer work, and pipeline construction projects. Its smooth drum attachment offers the versatility needed for special tasks, eliminating the need for entirely new equipment investments. The fully sealed exciter housing, paired with a robust hydraulic system, ensures an extended lifespan for the vibratory system, maximizing equipment uptime and efficiency.

Walk Behind Roller Compactor Applications

Horizont Machinery's Walk-Behind Roller is a compact dynamo ready for major tasks. It offers unmatched flexibility with its high output and adaptable functions. In construction, it's the range of uses, not size, that counts.

Multi-Use for Construction Demands:

- Earthwork and Asphalt: Ideal for foundational compaction in any construction.

- Paths: Delivers precise, efficient compaction for walkways and bike lanes.

- Sports and Recreation: Ensures smooth, safe surfaces for athletic fields and parks.

- Rural Roads: Capable in both creating and upkeeping access for countryside areas.

- Forestry Trails: Performs reliably on rugged forest tracks to maintain accessibility.

Horizont Machinery's equipment is not just about capability, but about enhancing project potential.

FAQs About Walk Behind Roller Compactor

-

What does a walk behind roller compactor do?

Compared to ride-on vibratory rollers, walk-behind rollers are economical construction equipment used for compacting soil, gravel, concrete, or asphalt in the road and foundation construction. It consists of an engine, 1 or 2 steel drums, and handlebars. An engine powers a rolling steel drum to compact the material. The power of the engine and the width of the drum vary according to the application scenario of the roller. Walk-behind road rollers are used in a variety of construction projects, from the construction of roads, driveways, and foundations to the backfilling of ditches. They are easy to operate, efficient, and provide a high-quality finish to projects.

-

What are the walk behind roller compactor size and weight?

Walk-behind rollers come in a variety of sizes and weights so they can be used in a variety of applications. Our smallest single-drum walk-behind rollers are typically around 600mm wide and weigh around 300kg, such as the HSR600B. The larger double drums can be up to 750mm wide and weigh up to 920kg, such as the HDR900DZ. The size and weight of the roller will determine the amount of soil or asphalt that can be compacted in a single pass.

-

What size roller do I need for the driveway?

A walk-behind roller is a great way to level a driveway, the size you need depends on the type of driveway you have. For driveways with larger gravel or stones, you may need more powerful rollers such as the HDR900DZ walk-behind rollers and HDR800DZ walk-behind Rollers. For driveways with less gravel or asphalt, smaller rollers with less power will suffice, such as the HSR600B single drum walk-behind rollers and HDR600E economical walk-behind rollers. If you plan to use your roller for multiple applications, such as compacting soil or asphalt, then you may need a more powerful roller. The size of the roller you need depends on the job you want to do and the application.

-

How do I fix compacted clay soil?

To remediate overcompacted clay soil, often indicated by visible cracking, consider these steps: reduce traffic on moist soil to prevent further compaction, integrate granular soil to improve texture, or use a compactor with lower impact force for gentler soil treatment.

-

Can I use a walk behind roller compactor instead of a plate compactor?

For larger surfaces, walk-behind rollers are an excellent alternative to plate compactors. It is commonly used in the construction of roads and other larger projects. This type of walk behind roller compactor is much more efficient than a vibratory plate compactor because it can cover a larger area in less time. It is also more powerful than a plate compactor and can compact harder surfaces and materials. However, it is important to note that a walk-behind roller is not ideal for small surfaces as it can be difficult to maneuver and control.

When compacting cohesive soils such as clay or silt, particularly for trench backfill, a walk-behind roller with a padfoot drum is recommended. Conversely, a plate compactor or a walk-behind roller with a smooth drum should be chosen for compacting granular soils or asphalt.