Pick a water pump is not merely a matter of randomly grabbing any model. It's vital to sift through the sizes and types, aiming for a match that's just right for your dewatering needs. The pump universe is diverse, with each variant boasting its own liquid-moving quirks. Opting for a pump that's on the smaller side could lead to lackluster water eviction. On the flip side, a mammoth pump might deplete its aqua reserve and grind to a halt, sparking onsite hiccups.

Once you've nailed down your pump choice, it’s key to dive into water, sludge, and mud maneuvering with precision and care. Navigating this correctly is a bulwark against both immediate and future site challenges. This guide is sprinkled with varied insights to aid you in decrypting the water pump selection code.

What is Dewatering?

Dewatering is essentially the act of removing surface or groundwater from a designated spot. It's a standard procedure at construction or excavation sites, where water is typically drawn out from wells, sumps, or mysterious pits. This activity usually sets the stage before any digging commences.

Why Bother with Dewatering?

Dewatering sits as a cornerstone in the early stages of construction. If you let surface and subsurface waters run amok, they transform into formidable foes during the building's construction and lifespan. Mastering dewatering is key for several pivotal reasons:

- Flood Outmaneuvering: Floodwaters, potentially teeming with unwelcome pollutants, can wreak both short and long-term structural chaos.

- Structural Integrity Preservation: Soil turned soggy can undermine the foundations.

- Erosion Deterrence: Lack of dewatering focus might pave the way for erosion.

- Protecting Environment and Health: If water loaded with pollutants is mishandled, it can spell trouble for nearby ecosystems and public health.

- Ensuring Worker Safety: Dewatering done right translates to stable grounds and safer workers.

- Time and Budget Considerations: Water-logged sites can trigger project delays and inflate labor costs. Keeping an eye on weather patterns and having a dewatering game plan is strategic.

In your quest for the ideal water pump, infuse these considerations to ensure your pick resonates with the unique demands of your project.

What to consider when choosing a pump?

Embarking on the mission to select an appropriate water pump, one must navigate through a labyrinth of critical factors.

- Liquid Diversity and Quantity

Confronting liquids like chemicals, fuels, or corrosive substances demands a pump designed for such challenging encounters. A well-chosen pump adapts to the fluid's temperament and corrosiveness, warding off potential breakdowns or the need for repairs.

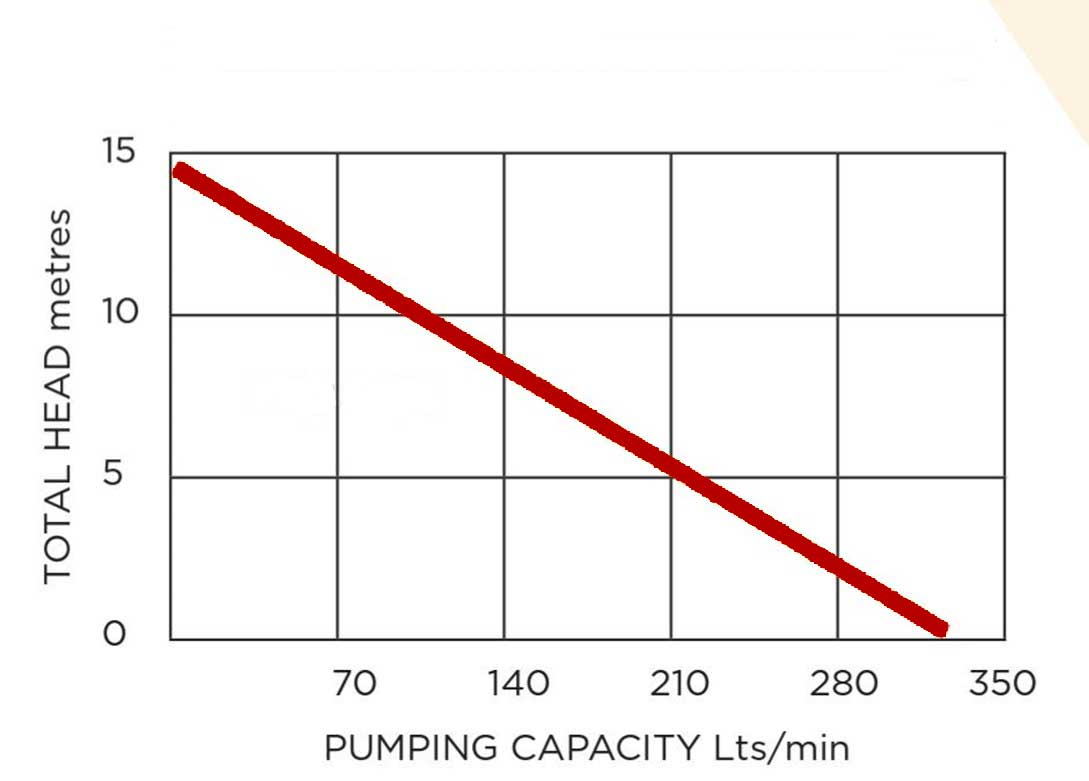

- Grasping Head Pressure

Head pressure is the vertical disparity measure between where the liquid starts its journey and where it bids farewell. Pump makers plot this head pressure against the pump's flow rate, creating a performance map. The head pressure takes its stance on the Y-axis, while the flow rate, the measure of the water volume moved, occupies the X-axis.

This performance map is a navigational tool, ensuring your pump choice meets the demands of your project's elevation and liquid type. Generally, pumps are utilized for elevating liquids.

For minor dewatering operations, a pump with modest pressure suffices. In contrast, larger-scale endeavors call for pumps with significantly more gusto in the pressure department.

Water Pump’s Flow Rate

The urgency of your task dictates the flow rate you’ll require. Accelerated operations call for heftier pumps, equipped with broader port sizes.

Essential Insight: The flow rate is essentially how much liquid the pump can usher through in a set time.

By weaving through these varied considerations, you're charting a course towards selecting a suitable water pump for your needs. Furthermore, a consultation with the Horizont experts can illuminate your path, particularly with queries like:

- Can the pump achieve rapid water removal?

- Is ongoing vigilance of the pump's performance necessary?

- Does the pump boast enough strength for your specific requirements?

Type of World of Water Pump

When it comes to water pumps, there's a variety to choose from, each with its unique features.

Submersible Pumps

Submersible pumps are designed to work underwater and can handle high-pressure and high-flow wastewater. They have a sealed motor and are closely connected to the pump body. While they excel in many areas, they are not suitable for thick liquids like mud and sludge. Submersible pumps have advantages such as not needing priming, being compact, having a float switch for liquid level detection, and being portable with few components.

These pumps are commonly used for dewatering, groundwater pumping, and fluid transfer in industries like mining, civil engineering, construction, and DIY tasks like emptying pools or post holes. Horizont offers a range of submersible pumps, including single-phase and three-phase options.

Diaphragm Pumps

Diaphragm pumps are versatile positive displacement pumps suitable for various liquids, including clean water and viscous substances. They are self-priming and can handle slurry and liquids with small solids. Diaphragm pumps work by flexing a diaphragm to move water from one place to another.

These pumps are used in industries that require liquid transfer due to their efficiency and accuracy. They are also known for their suction lift characteristics. If you need to deal with silt and sludge, diaphragm pumps can handle it but keep in mind that their pumping capacity may reduce in such cases. Horizont offers various diaphragm pumps for different needs.

Trash Pumps

Trash pumps are designed to handle small debris and solids up to 29mm in size. They have larger impeller veins and a robust pump housing. These pumps don't grind up the solids but separate them and eject filtered water. They are essential for situations where water is clogged with mud and debris.

Horizont provides a Diesel Trash 100mm Pump and a low-noise trash diesel pump for industrial use. These pumps can handle raw sewage, water with solids, and sludge.

HWP Portable Water Pump

Portable Water Pumps are portable and self-priming pumps with flexdrive motors. They are suitable for clean and dirty water with a high flow rate. These pumps come with roll cages for easy transportation and maneuverability.

Portable water pumps are great for dewatering and drainage applications, especially when you have time constraints. They are also useful for draining hard-to-reach places. Horizont offers 50mm and 80mm portable water pumps for different flow rates.

These are the main types of water pumps to consider, each with its specific capabilities and applications.

Choosing the Perfect Water Pump with Horizont

Selecting the ideal water pump for your project can be quite a task, but fear not! With a little research and a chat with your friendly local Horizont team, you'll be on the right track.

Ready to get started? You can easily reserve all the equipment you require online. Making the right choice has never been this convenient.